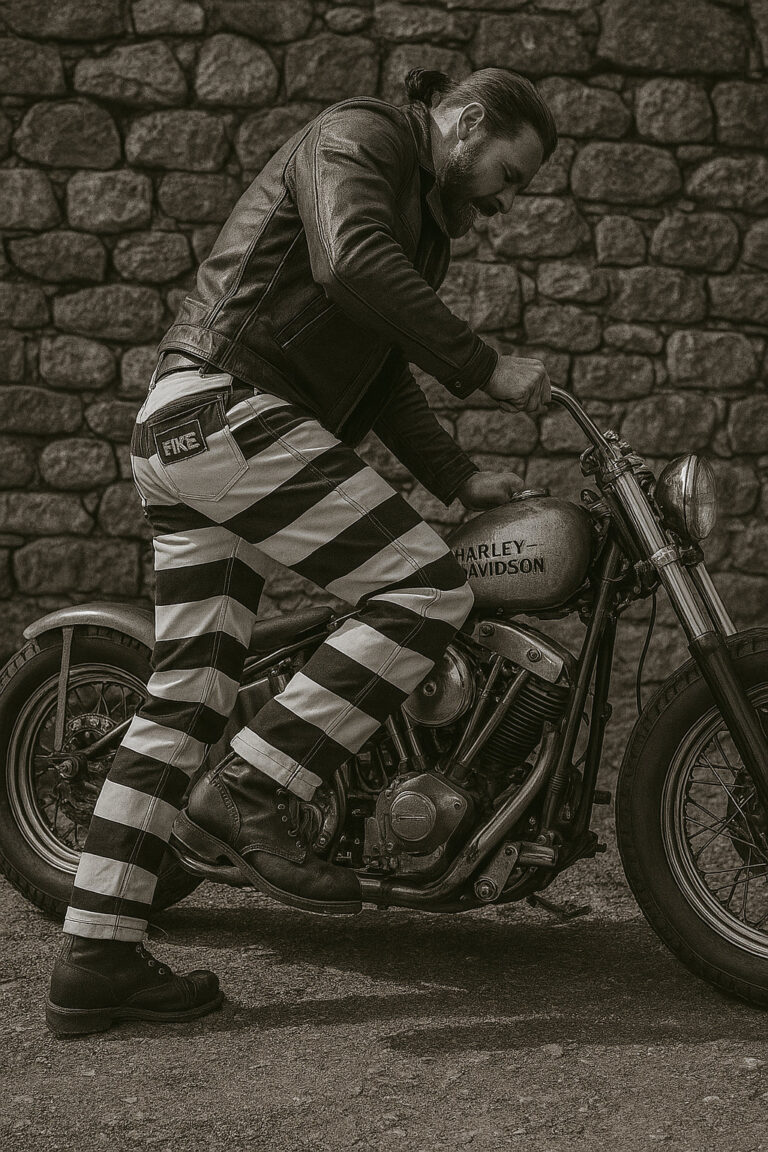

Nicolas rides a 1986 1340 Evolution Sportster and an occasional Shovelhead.

Nicolas is a free spirited biker who loves to ride his Harley Davidson motorcycle and continues to build it over time, as they say “A biker’s work is never done”. He is always riding in search of new rides to experience and loves our alpine mountain roads. He is an enthusiast who is always ready to have a good time and loves to get involved in all kinds of activities, it is with him that the school-of-cool adventure started in 2018.

The Sportster Evolution engine

The Sportster engine hasn’t changed much since its introduction in 1952. It uses the same engine box architecture as when it was upgraded to the Evolution engine in 1986. This allows for a unique valvetrain configuration. The Sportster Evolution is one of the few engines that still uses four camshafts to drive its overhead valves. Each shaft has a lobe and they are all gear driven. The cam lobes are located on an almost horizontal line and form, with their gears placed in a fan, a sort of cascade. The connecting rods are arranged two by two (front and rear) parallel to the cylinder axis which allows each tappet to move away from the cam lobes perpendicular to the plane of the lobes.The Sportster Evolution engine was used by Buell Motocycle for its line of sport bikes from 1986 to 2010. This configuration works well for radical, high-efficiency cams, making it a natural choice for the Harley-Davidson-owned brand.

Changes

The Sportster Evolution engine has remained unchanged from 1986 to the present, although changes to the transmission, final drive mount and engine mounts have required modifications to the Sportster Evolution package. Construction is almost entirely identical between the 883 and 1200cc versions; the main difference between the two is a smaller bore on the 883cc (inherited from its older Ironhead parent), with slightly different head covers. Conversions from 883 to 1200cc are relatively inexpensive and common 3, and cheaper than buying a new motorcycle4 with a 1200cc engine. Carburetors were standard on Sportster engines until 2007, when they were replaced by a Delphi sequential electronic fuel injection system.The Buell Blast motorcycle used a simplified engine derivative (single-cylinder switch) from 2000 to 2009. The Sportster engine used on the Buell Blast was largely similar to the one used on the Sportster, although modifications were made to reduce overall costs and maintenance, such as removing the rear cylinder.The Big Twin’s Evolution engine was produced for fifteen years and was used in Harley-Davidson’s Dyna, Softail, FXR and Touring models. A limited number of Evolutions were also used in CVO models for the 1999 FXR2 and FXR3 and the 2000 FXR4. The main case was only slightly modified from the previous Shovelhead engine, but the top end of the head was significantly improved.The 1,340cc Evolution uses a single-geared four-lobe camshaft located just above the crankshaft axis. While this simplifies camshaft replacement, it complicates things with pushrods and pushrods each deflecting at different angles. The Big Twin connecting rods have a distinct helical appearance because they are perpendicular to each other.The Big Twin is the most iconic Harley-Davidson engine, with a rich history dating back to the Knucklehead. Today, it remains an important part of the company’s lineup, along with a wide range of accessories and aftermarket clones produced by third parties.

Nicolas’ video on his Shovelhead

The Shovelhead is an iconic motorcycle engine produced by Harley-Davidson from 1966 to 1984 that succeeded the Panhead engine. At the beginning of its production, compared to the previous engine, the Shovelhead had shallower combustion chambers, larger intake and exhaust valves, improved combustion, and reinforced valves and pistons; giving the new engine ten more horsepower with a different appearance from the best engines of its time1. The engine earned the nickname “Shovelhead” due to the appearance of the rocker heads, which were traced back to old overturned coal shovels2. Although the engine quickly ran into problems, it helped Harley-Davidson increase sales by 26% in the first year of production.

A little bit of history…

The owners of Harley-Davidson demanded more power, so the Shovelhead engine was born! This powerful engine has undergone many modifications over the years to improve cooling and oil consumption. In its early stages, the engines had only ten cooling fins that did not provide sufficient cooling. Another problem was the oil that was accumulating in the cylinder heads, causing valve leaks and combustion of that oil. The oil also stagnated in the sump instead of being properly sucked in, causing overheating and lower performance.Of motor problemsLeaks and oil consumption were a big problem for motorcycles equipped with this engine. Many homeowners said they would lose up to 1/4 litre of oil every five hundred kilometres. Overheating of the engines also caused significant problems, often resulting in failures.Lack of oil and excessive temperature make the valves stick and destroy the engine. Many Harley technicians reported that without top engine modifications, these engines often only lasted 500 to 5,000 km4. Seeking to repair the engine rather than invest in research and development, Harley-Davidson found itself far behind the competition of the cheaper and more reliable Japanese motorcycles taking control of the market.In order to improve its financial situation, the company merged with American Machine and Foundry (known as amf). After taking over AMF, the company started using its own funds to try to improve the engine.In 1970, the alternator was redesigned to reduce stress and hidden behind a new side housing. The carburetors were changed by Zenith-Bendix, which began to give the engine a better image. However, in 1974, the engine encountered other, much larger problems. The 1973 oil crisis in the United States severely affected engine performance due to the low octane rating of gasoline. This caused shocks that caused overheating and expansion of the seals, damaging the bolt bolts.

In search of a solution

Despite some production problems, the AMF was able to produce more units in 1976. Unfortunately, this gave the company’s employees a bad reputation and reduced the quality of their work. After realizing that they needed serious transformations to improve the situation, they improved the engine in 1978. These corrections consisted mainly of a displacement increase (from 1200 to 1340 cm3), a new gearbox and a new internal design of the oil pump to improve oil circulation and cooling.However, these changes were not enough to improve the poor quality of American fuel at the time. While the valves and guides were weakened by overheating and detonation, oil consumption remained high. Another problem arose in 1979 with engines equipped with electronic ignition, which were likely to fail. Many owners have replaced them with a more conventional switching system to improve reliability. The higher compression ratio on the new engines also remained a major problem, due to the low fuel quality and low octane content. Harley-Davidson realized that many Shovelhead owners needed to adapt spare parts to make their bikes work properly; it was time for the company to develop a new engine.

Ultimately…

As production of the Shovelhead drew to a close, Harley-Davidson made several modifications to keep the engine on the assembly lines. In 1980, they added a belt transmission to prevent oil leakage from the chain transmission, as well as a five-speed transmission and rubber brackets to reduce vibration. Then, in 1981, they bought the shares of the AMF. The engine received a new oil pump, improved valve guides, and the compression ratio was reduced, allowing the engines to run on substandard gasoline sold in America. It continued to be manufactured until 1984, when aluminum cylinder heads and cylinders gradually began to take control of most models with the Evolution block soon replacing it completely in 1985, with the exception of some models like FLH.

Bikers | Bikers | bobbers | Harley davidson | Photos

Bikers | Bikers | bobbers | Harley davidson | Photos Bikers | Bikers | bobbers | bobbers | Harley davidson | Harley davidson | japan style | Pantalon prisonnier

Bikers | Bikers | bobbers | bobbers | Harley davidson | Harley davidson | japan style | Pantalon prisonnier